Was the first time that iron and steel were produced in the area of Riesa.

The brothers Heinrich and Alexander Schönberg received permission to construct an iron and steel plant in Riesa. Following English standards, ore and coal were smelted into raw iron in puddling furnaces, using steam hammers. The construction of a rolling mill secured the further processing of the iron.

The duke of Einsiedel purchased the steel plant.

The importance of railroads and engineering increased, furthering the fields of use for iron. Axles and connection plates were important products of the steel plant in Riesa. Patented welding was used for pipes from the additionally constructed pipe plant. Due to its prime position along the river routes of the Elbe and the railroad between Dresden and Leipzig, Riesa was able to achieve a leading position in the heavy industries.

different steel components were continuously produced. During World War I and II it was mainly military equipment.

Complete deconstruction of the steel plant, in order to pay reparations towards the Sovjet Union.

After the rebuilding the first iron is cast in the new plant in Riesa.

Riesa's steel production was roped into the planned economy of the GDR. The plant became one of the flagship producers, caring for its associates with its own clinic, leisure center, sports complexes and holiday homes.

Founding year of Feralpi Siderurgica in Lonato (IT).

With the German reunification the “Stahl- und Walzwerk Riesa AG” was founded as a corporation, in order to save the existing jobs. Due to the technologically obsolete equipment as well as the collapse of the traditional markets in Eastern Europe, the undertaking of this proved futile.

The italian steel producer Feralpi Siderurgica purchases 230.000m² of property, to construct a modern steel plant. In preparation almost all of the existing plant is disassembled.

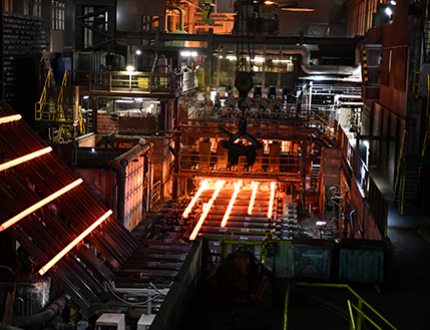

With the foundation of Elbe-Stahlwerke Feralpi GmbH on historical grounds in Riesa, a new 75t electric arc furnace, ladle furnace, strand furnace with 4 lines and the rolling mill for reinforcing steel were installed. All in all one of the most modern plants in Europe was constructed with different instruments to fulfill all internal and external environmental requirements.

Was the opening of the new rolling mill. An annual 500.000 tons of steel are being produced at the plant.

Foundation of Elbe-Schrott-Recycling and construction of the new shredder plant. This makes for efficient and low-cost scrap metal supply.

A total of 600.000 tons of steel and 470.000 tons of wire rod are produced. This productivity enables the employment of a total of 370 associates.

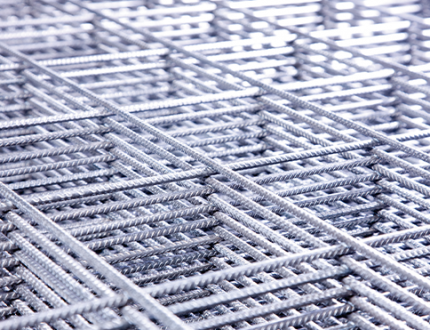

The wire plant started with the production of bearing and list mats. In the steel plant parts of electrical energy are replaced by a oxygen-gas-mixture. For this an air separation unit by “Air Liquide” is installed on the grounds, eliminating the dangerous transportation of liquid oxygen in tank wagons.

Unification of Elbe-Schrott-Recycling and Elbe-Stahlwerke Feralpi GmbH.

Foundation of Feralpi Holding S.p.A. in Italy, which takes over the management and administration of all businesses in and outside of Italy.

Was the 40-year anniversary of the Feralpi Group, and a milestone of one million tons of steel were produced in Riesa. With roughly 600 associates, 1 million tons of steel are produced each year in Riesa.

The technology for air quality management is registered as best practice at the Federal Environment Ministry.

Dioxin measurements reach their lowest level so far in the history of the plant.

The first sustainability report for Riesa was published. The scrap metal building is closed over the entire length of 150m, reducing dust and noise emissions effectively. The handling of the shredder light fraction takes place in a closed container system, minimizing dust detachment.

Issuing of the license of modification §16 BImSchG for energy production from the waste heat of the steel production. New vehicles for moisturization of roads and transfer sites, as well as new power sweepers, are put into operation. Validation of the first environmental declaration following EC decree number 1221/2009 (EMAS III) and registration for the European EMAS register for all companies in Riesa.

The Feralpi plant in Riesa celebrates its 20 year anniversary.

Recipient of the Saxon Environmental Award for the new steam and energy production plant. To work more closely with the public, different informative campaigns, talks with citizens and round tables are implemented.

First certification after DIN EN ISO 50001 for the steel plant. The license of modification from 2012 is furthered to a total capacity of 1.4 million tons for the steel plant and 1.2 million tons for the rolling mill a year with far reaching environmental and procedural modernization measurements. These include sound insulation and ventilation optimization of the production.

Communication and transparency are improved by regularly publishing official emission measurement reports on the company website.

Feralpi Stahl is included in the intersectoral excellency initiative for climate protection as the first Saxon company for its outstanding achievements concerning climate and environmental protection and as a pioneer in the conservation of energy.

The first consolidated non-financial declaration was published in accordance with transparency and reporting.