OUR WAY TO GREEN STEEL

A commitment we have been supporting for over 20 years

The sustainability strategy guides our actions towards creating value for people, the environment, customers and society.

With transparency we report our non-financial performance since 2004.

We integrate sustainability into the industrial plan to offer you low-emission, zero-waste steels and to generate positive impacts on value chains.

Inspired by ESG principles, we develop an increasingly sustainable electro-steel production, offering you the best environmental and quality performances across the entire range of our steels for construction.

We do this thanks to the best available technologies, renewable energy and the reduction of the use of raw materials. We invest to reach ambitious targets.

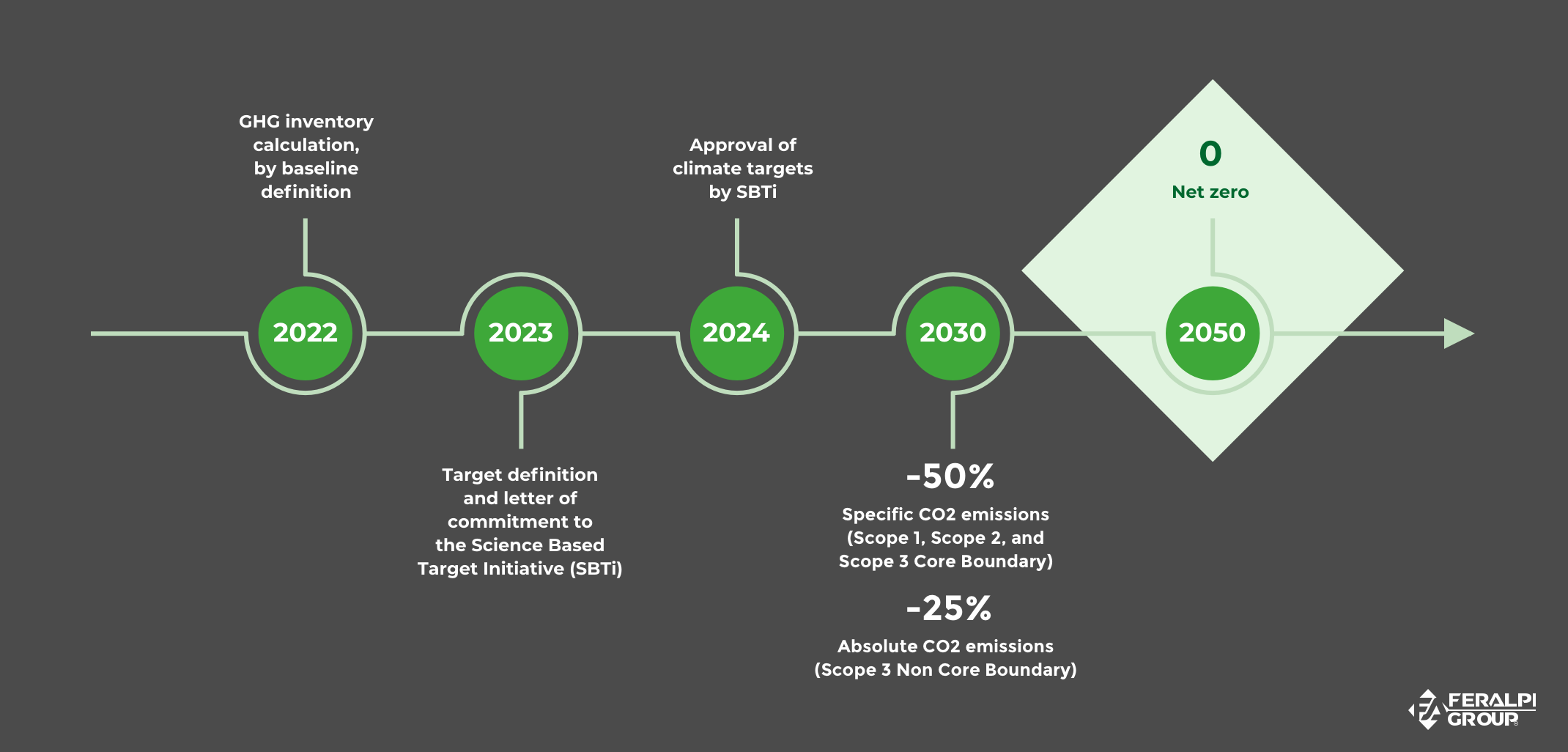

In 2024 we defined 14 KPIs through our ESG Scorecard. We have voluntarily chosen the path of science to set the targets for reducing CO₂ emissions for 2030 that have been approved by the Science Based Targets Initiative (SBTi) and that we pursue through verifiable action plans.

Our daily commitment is to cooperate with all partners along the value chain to strengthen the development of a sustainable business model.

Giuseppe Pasini

President Feralpi Group

“We respond to the needs of a market that is evolving towards products that are not only high quality, but also decarbonized. We continue to invest in industrial processes by collaborating with the most important technological partners to always be at our customers side.”

Uwe Reinecke

General Manager FERALPI STAHL

“The new zero-direct emission rolling mill built in Riesa is a value for our customers. With the most advanced technologies we reduce emissions and strengthen the competitiveness of our supply chain.”

What is FERGreen?

Find out what's inside each of our building products

FERGreen®. Transparency is the value that unites us

FERGreen stands for transparency and responsible business practices - and for sustainable partnerships in the construction industry.

We have been producing our reinforcing steel in Riesa in an electric arc furnace (EAF) for over 30 years. This makes us a pioneer in the production of resource-saving steel.

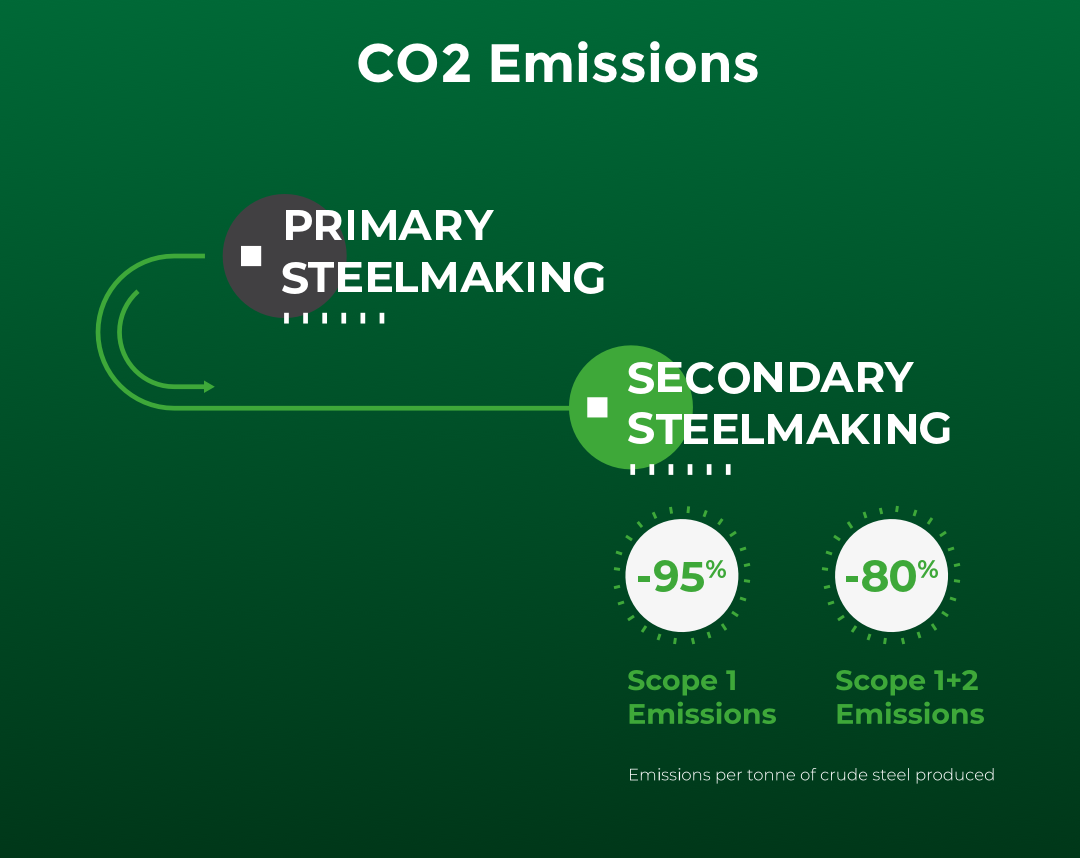

The direct CO2 emissions of our secondary steel production are over 90 % lower than those of primary steel production! As a result, our technology produces 80% lower Scope 1+2 emissions compared to conventional steel production from a blast furnace.

-

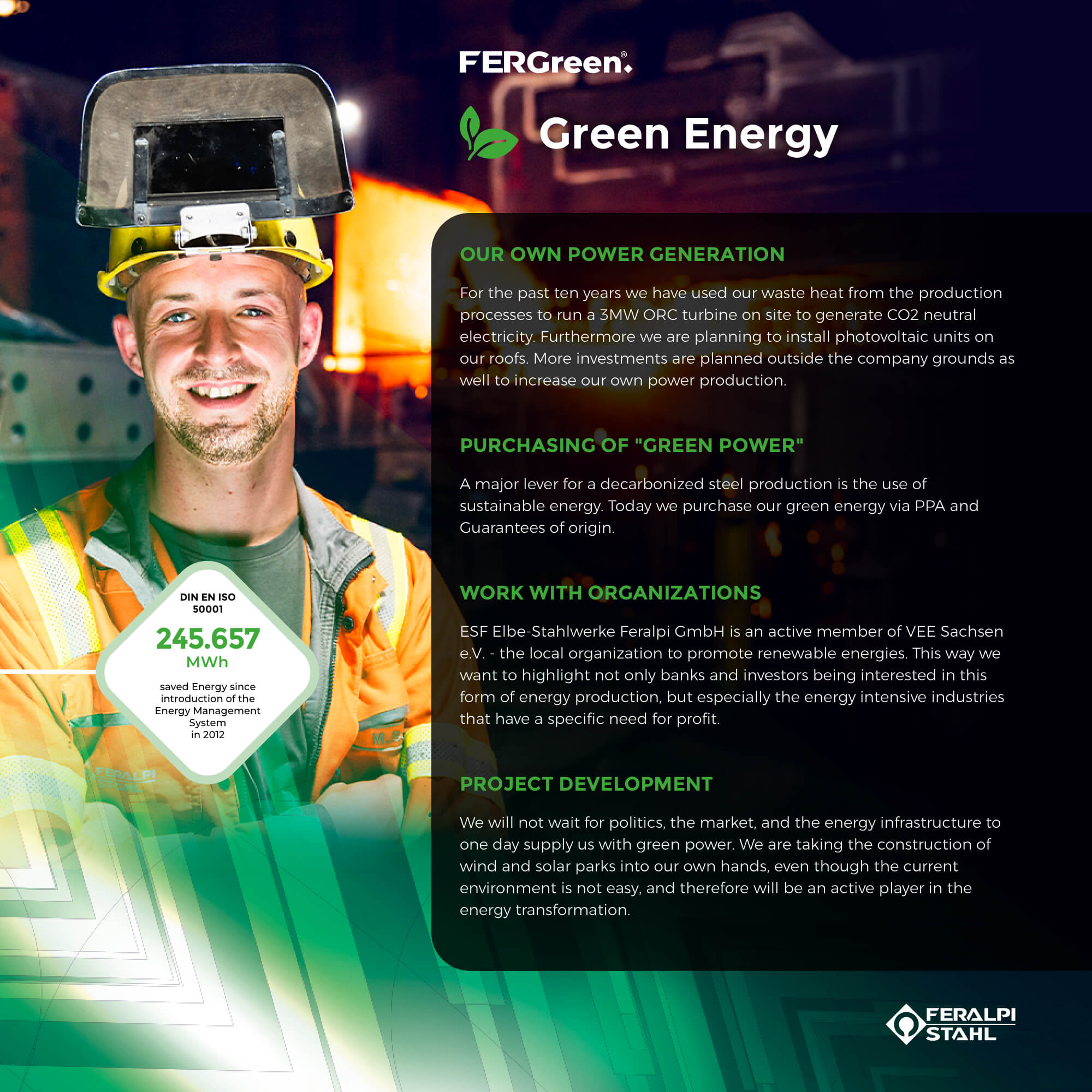

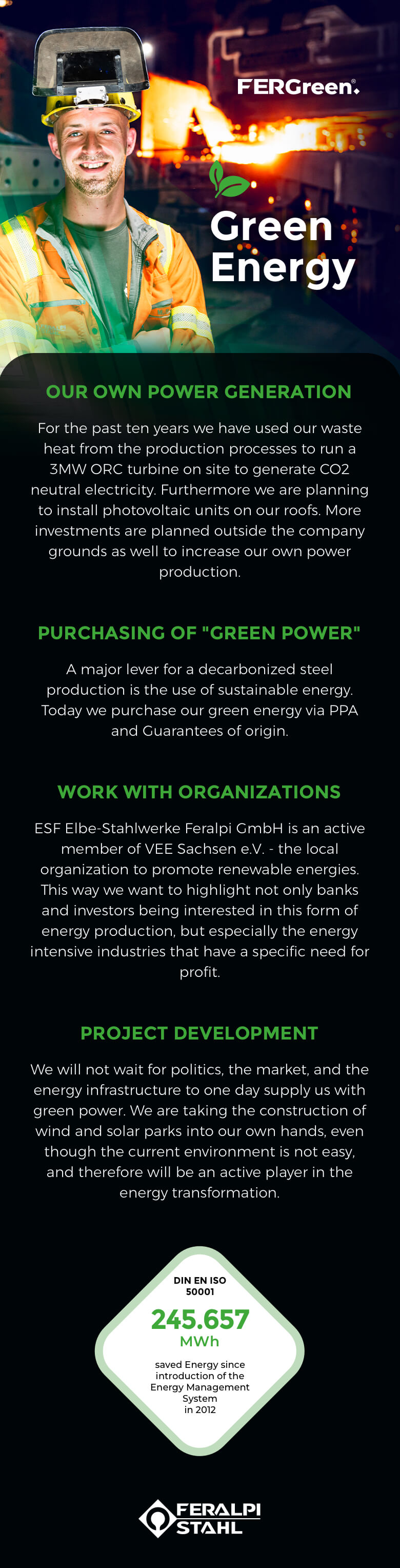

Green Energy

Green Energy

Image Image

Image

-

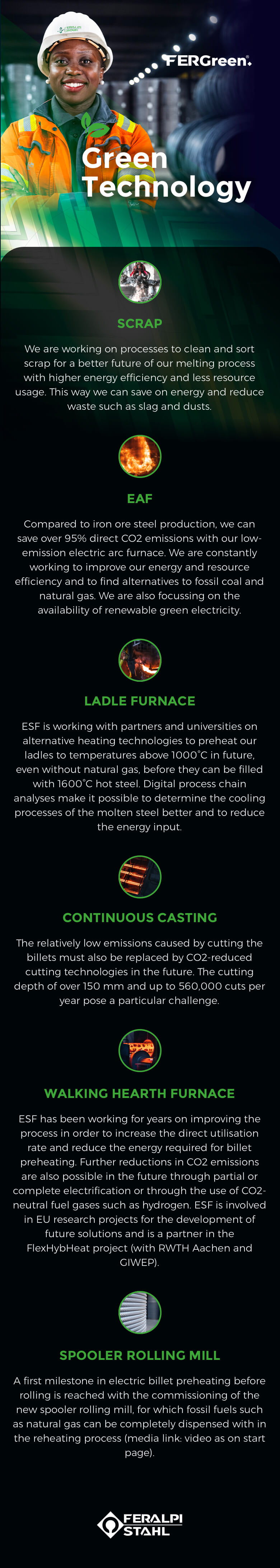

Green Technology

Green Technology

Image Image

Image

-

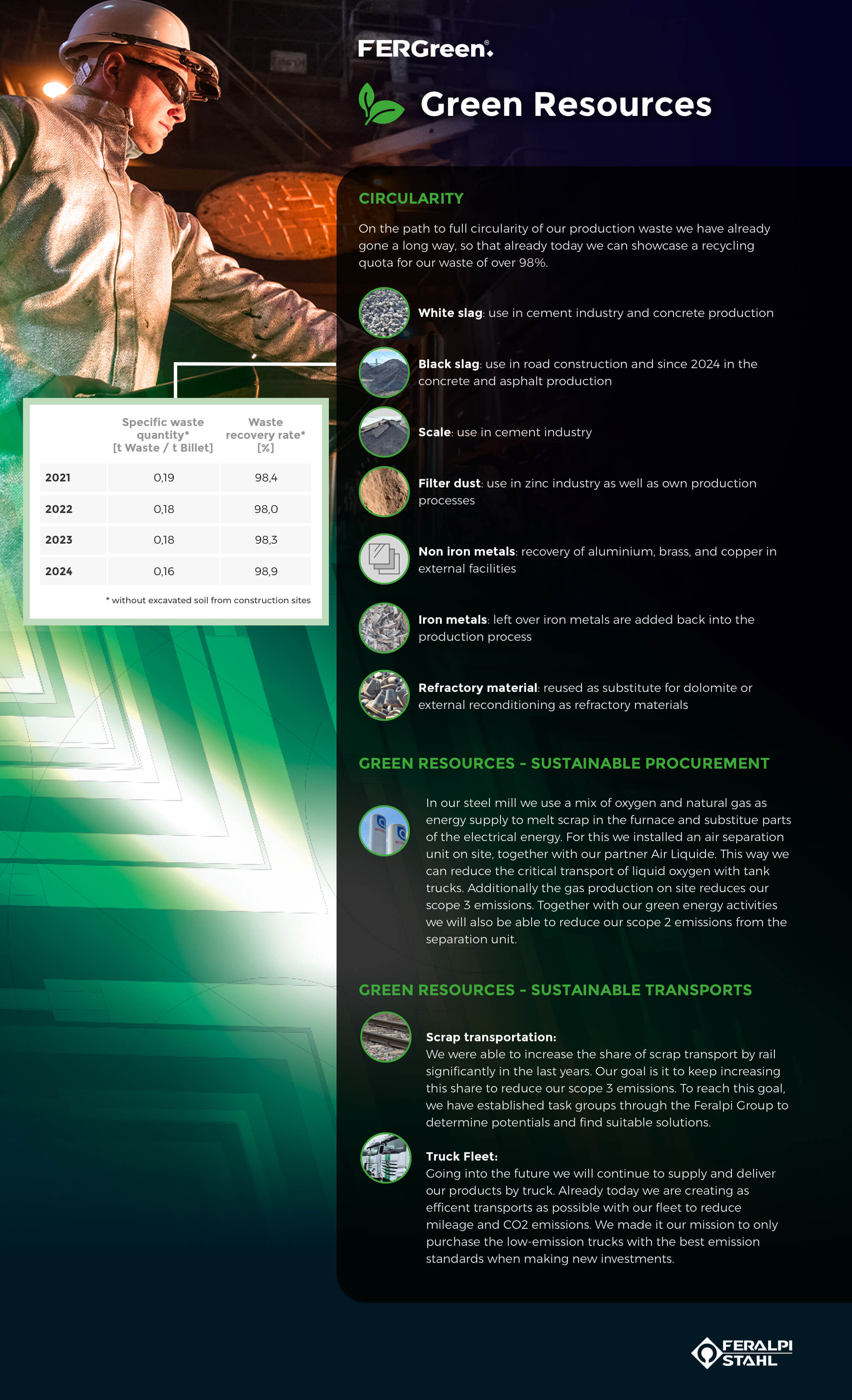

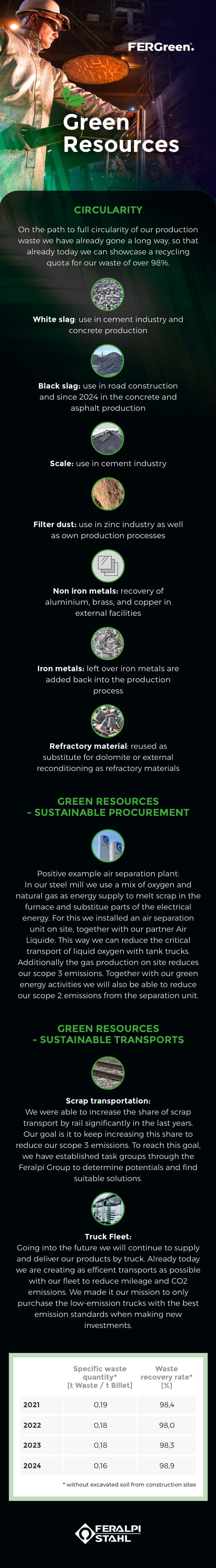

Green Resources

Green Resources

Image Image

Image

Dr. Mathias Schreiber

Director Integrated Management System (IMS)

“Our commitment to the environment is not an empty promise, but has always been the basis of our actions.”

Feralpi Stahl - Our Offer

FERGreen is a central building block for our company strategy and is based on important investments towards sustainable technologies: This way we meet the highest requirements for sustainable construction industry. In addition to high quality, all our steel products are characterized by the following properties:

OUR FERGREEN PRODUCTS

With FERGreen, the Feralpi Group offers a pioneering product line for the entire construction industry. FERGreen is an expression of our comprehensive ESG commitment and combines technological innovation with concrete sustainability goals: measurable, certified, and transparent. In this way our steels leave a measurably smaller ecological footprint.

Thanks to the environmental and qualitative performance of our products, we are the best ally for your business and for your sustainable construction projects. To learn more about the environmental and climatic performance of our products, click here:

Select a product:

-

Billets

Environmental Product DeclarationImage

The Environmental Product Declaration contains many environmental indicators; one of the most important is the GWP (Global Warming Potential), which gives a measure of the carbon footprint of our products.

The GWP-total (A1-A3) value of our FERGreen products has already decreased by more than 30% compared to the base year 2022 (base year).

2022459kgCO2e/tToday289kgCO2e/t2050Near ZeroMinimum content of recycled, recovered and by-product materialsAt Feralpi Stahl in Riesa, we live a circular economy: we produce our reinforcing steel almost entirely from scrap - and thus transform waste material into a valuable raw material.

Our reinforcing steel has a minimum content of recycled, recovered and by-product material of

98.6 -

Spooler Coil

NEW

Environmental Product DeclarationImage

The Environmental Product Declaration contains many environmental indicators; one of the most important is the GWP (Global Warming Potential), which gives a measure of the carbon footprint of our products.

We have built our new hot rolling mill B. For our future. For Green Steel made in Riesa.

What once started as a vision has now become reality. We are proud to be able to offer you our innovatively produced, low-emission direct-spooled coil for your sustainable construction projects.

2022Our visionScope 1 Emission-free hot rolling

Green Energy

Directly spooled

CoilToday296kgCO2e/t2050Near ZeroMinimum content of recycled, recovered and by-product materialsAt Feralpi Stahl in Riesa, we live a circular economy: we produce our reinforcing steel almost entirely from scrap - and thus transform waste material into a valuable raw material.

Our reinforcing steel has a minimum content of recycled, recovered and by-product material of

98.6 -

Wire Rod

Environmental Product DeclarationImage

The Environmental Product Declaration contains many environmental indicators; one of the most important is the GWP (Global Warming Potential), which gives a measure of the carbon footprint of our products.

The GWP-total (A1-A3) value of our FERGreen products has already decreased by more than 30% compared to the base year 2022 (base year).

2022587kgCO2e/tToday368kgCO2e/t2050Near ZeroMinimum content of recycled, recovered and by-product materialsAt Feralpi Stahl in Riesa, we live a circular economy: we produce our reinforcing steel almost entirely from scrap - and thus transform waste material into a valuable raw material.

Our reinforcing steel has a minimum content of recycled, recovered and by-product material of

98.6 -

Reinforcing Steel in Bars

Environmental Product DeclarationImage

The Environmental Product Declaration contains many environmental indicators; one of the most important is the GWP (Global Warming Potential), which gives a measure of the carbon footprint of our products.

The GWP-total (A1-A3) value of our FERGreen products has already decreased by more than 30% compared to the base year 2022 (base year).

2022593kgCO2e/tToday368kgCO2e/t2050Near ZeroMinimum content of recycled, recovered and by-product materialsAt Feralpi Stahl in Riesa, we live a circular economy: we produce our reinforcing steel almost entirely from scrap - and thus transform waste material into a valuable raw material.

Our reinforcing steel has a minimum content of recycled, recovered and by-product material of

98.6 -

Reinforcing Steel in Coils

Environmental Product DeclarationImage

The Environmental Product Declaration contains many environmental indicators; one of the most important is the GWP (Global Warming Potential), which gives a measure of the carbon footprint of our products.

The GWP-total (A1-A3) value of our FERGreen products has already decreased by more than 30% compared to the base year 2022 (base year).

2022599kgCO2e/tToday381kgCO2e/t2050Near ZeroMinimum content of recycled, recovered and by-product materialsAt Feralpi Stahl in Riesa, we live a circular economy: we produce our reinforcing steel almost entirely from scrap - and thus transform waste material into a valuable raw material.

Our reinforcing steel has a minimum content of recycled, recovered and by-product material of

98.6 -

Electrowelded Mesh

Environmental Product DeclarationImage

The Environmental Product Declaration contains many environmental indicators; one of the most important is the GWP (Global Warming Potential), which gives a measure of the carbon footprint of our products.

The GWP-total (A1-A3) value of our FERGreen products has already decreased by more than 30% compared to the base year 2022 (base year).

2022608kgCO2e/tToday386kgCO2e/t2050Near ZeroMinimum content of recycled, recovered and by-product materialsAt Feralpi Stahl in Riesa, we live a circular economy: we produce our reinforcing steel almost entirely from scrap - and thus transform waste material into a valuable raw material.

Our reinforcing steel has a minimum content of recycled, recovered and by-product material of

98.6

Ralf Schilling

CEO Feralpi Stahlhandel GmbH and Feralpi-Logistik GmbH

“Feralpi Stahl is the sustainable partner at your side.”

Certificates

Environmental Product Declaration

Building a sustainable future for Feralpi Stahl

Sustainable construction is successful when the environmental impact of the building materials used is certified and reduced.

With Feralpi Stahl environmental certifications, you receive clear and transparent standardized information on the environmental aspects of our reinforcing steel, based on a detailed analysis of the product life-cycle, from the supply of raw materials to the end-of-life phase of the product.

-

Billets

Technical data

Product category rules (PCR) PCR 2019:14 Construction products, Version 1.3.4 EPD system boundaries Cradle-to-gate with options and with optional modules (A4) GWP-t (A1-A3) 289 kgCO2e/t Environmental Product Declaration (EPD) EPD-IES-0017968 Certificate (ICMQ) ICMQ – 2500830EPD -

Spooler Coil | NEW

Technical data

Product category rules (PCR): PCR ICMQ001/15 for construction products (Rev. 3.1, 12/11/2024) EDP system boundaries: Cradle-to-gate with options, module C1-C4, module D and with optional modules (A4) GWP-t (A1-A3): 296 kgCO2e/t Environmental Product Declaration (EPD): ESF_001 Certificate (ICMQ) ICMQ – 2500900EDP -

Wire Rod

Technical data

Product category rules (PCR) PCR 2019:14 Construction products, Version 1.3.4 EPD system boundaries Cradle-to-gate with options, module C1-C4, module D and with optional modules (A4) GWP-t (A1-A3) 368 kgCO2e/t Environmental Product Declaration (EPD) EPD-IES-0018169 Certificate (ICMQ) ICMQ – 2500831EPD -

Reinforcing Steel in Bars

Technical data

Product category rules (PCR) PCR 2019:14 Construction products, Version 1.3.4 EPD system boundaries Cradle-to-gate with options, module C1-C4, module D and with optional modules (A4) GWP-t (A1-A3) 368 kgCO2e/t Environmental Product Declaration (EPD) EDP-IES-0018167 Certificate (ICMQ) ICMQ - 2500832EPD -

Reinforcing Steel in Coils

Technical data

Product category rules (PCR) PCR 2019:14 Construction products, Version 1.3.4 EPD system boundaries Cradle-to-gate with options, module C1-C4, module D and with optional modules (A4) GWP-t (A1-A3) 381 kgCO2e/t Environmental Product Declaration (EPD) EPD-IES-0018166 Certificate (ICMQ) ICMQ – 2500833EPD -

Electrowelded Mesh

Technical data

Product category rules (PCR) PCR 2019:14 Construction products, Version 1.3.4 EPD system boundaries Cradle-to-gate with options, module C1-C4, module D and with optional modules (A4) GWP-t (A1-A3) 386 kgCO2e/t Environmental Product Declaration (EPD) EPD-IES-0018168 Certificate (ICMQ) ICMQ – 2500834EPD

Integrated management system for environment, energy and quality

FERALPI STAHL is one of only two German steel plants which have been awarded the EMAS certificate, the EU's highest environmental management certification. Companies only receive this seal if their operational environmental and climate protection exceeds the legally required standard - which must be confirmed by annual audits.

We have carried the EMAS certificate without interruption since 2012.

FERALPI STAHL is also certified in accordance with ISO 14001, ISO 50001 and ISO 9001. Continuous striving for improvements in the areas of environment, safety and energy is also essential for this certification.

-

EMAS (Environmental management system in accordance with Regulation (EC) No. 1221/2009)

EMAS Certificate DE-144-00047 EMAS Environmental Declaration Umwelterklärung 2025 -

Environmental management system DIN EN ISO 14001

Environmental management system DIN EN ISO 14001 DIN EN ISO 14001 -

Energy management system DIN EN ISO 50001

Energy management system DIN EN ISO 50001 DIN EN ISO 50001 -

Quality management system DIN EN ISO 9001

Quality management system DIN EN ISO 9001 DIN EN ISO 9001

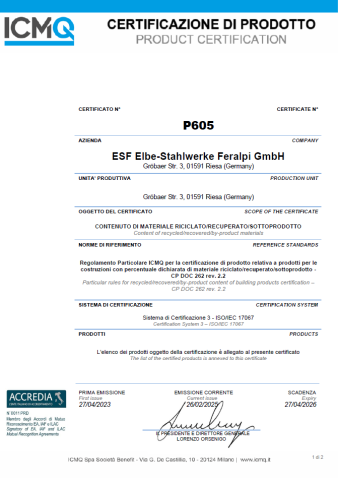

Minimum content of recycled, recovered and by-product materials

At Feralpi Stahl in Riesa, we practise a circular economy on a daily basis: we produce our reinforcing steel almost entirely from scrap - transforming waste material into a valuable raw material. On the one hand, we use scrap that has already completed its product life cycle (post-consumer scrap). On the other hand, we use new scrap that has accumulated, for example, in the production of our suppliers (pre-consumer scrap). In addition to post-consumer and pre-consumer scrap, other input materials such as ferroalloys are used for steel production at Feralpi Stahl. These alloys, including those with iron content, are taken into account in determining the recycled content.

All this information undergoes independent annual certification - for the common sustainability goals of Feralpi Stahl and our stakeholders.

Technical data

Product scope: Entire product range

Reference period: 01-01-2025 - 31.12.2025

| Standard | CP DOC 262 rev.2.2 (Accredia accredited) |

|---|---|

| Pre-consumer scrap | 6,7% |

| Post-consumer scrap | 89,8% |

| Total content of recycled, recovered, By-Product material | 98,6% |

| Certificate (ICMQ) | ICMQ – P605 |

Sustainability Report

Do you have further questions about the

ecological sustainability of our products?

Dr. Mathias Schreiber

Director Integrated Management System (IMS)

ESF Elbe-Stahlwerke Feralpi GmbH